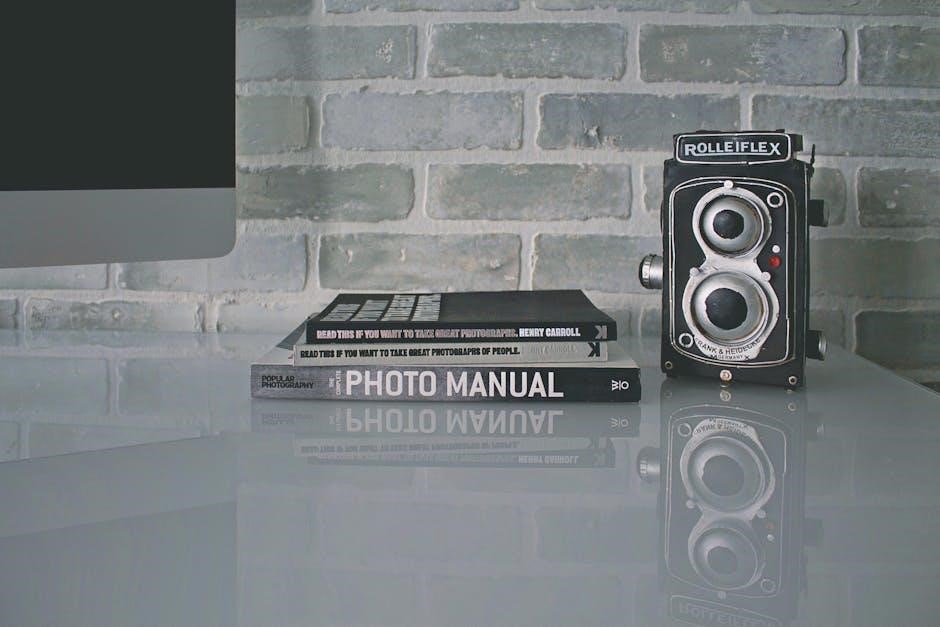

Books and manuals are essential resources for spreading knowledge‚ offering detailed insights into various subjects. They serve as foundational tools for education‚ professional growth‚ and skill development across industries.

The Evolution of Books and Manuals: From Print to Digital

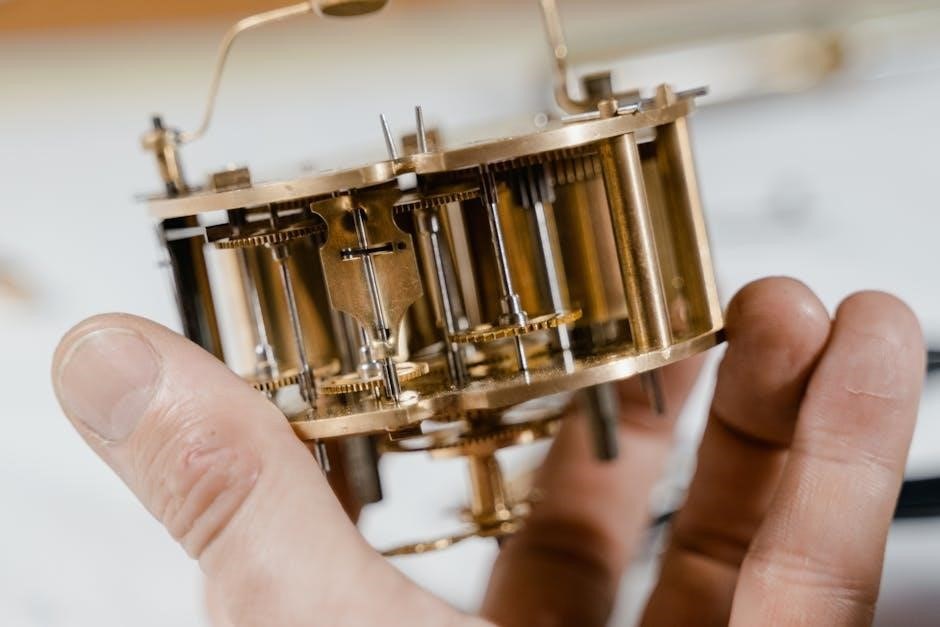

Books and manuals have undergone a significant transformation from traditional print formats to digital versions. The rise of technology has enabled the creation of e-books‚ PDF guides‚ and interactive manuals‚ making content more accessible and portable. Digital formats allow for real-time updates‚ multimedia integration‚ and enhanced search functionalities‚ improving user experience. This shift has been accelerated by advancements in AI‚ which now plays a role in content creation‚ personalization‚ and distribution. The transition to digital has also raised questions about copyright‚ energy consumption‚ and environmental impact‚ prompting discussions on sustainable practices in publishing.

Digital manuals and AI-driven tools are reshaping how information is consumed‚ offering customizable solutions for learners and professionals. This evolution reflects broader societal changes‚ balancing the convenience of digital with the enduring value of traditional print.

The Importance of Books and Manuals in Education and Professional Development

Books and manuals are indispensable in education and professional development‚ serving as comprehensive resources for learning and skill enhancement. They provide structured information‚ in-depth analysis‚ and practical guidance‚ enabling individuals to acquire knowledge systematically. In educational settings‚ textbooks and study manuals are vital for curriculum delivery‚ while in professional contexts‚ technical manuals ensure standardization and consistency. These resources support continuous learning‚ adaptability‚ and innovation‚ fostering personal and organizational growth. Their relevance extends across industries‚ making them essential tools for both beginners and experts seeking to refine their expertise. The shift to digital formats has further enhanced accessibility and personalization‚ ensuring these resources remain central to development.

The Impact of AI on Book Writing and Manuals

AI is transforming book writing and manuals by enhancing creativity‚ improving efficiency‚ and ensuring consistency. It aids authors in generating content‚ personalizing narratives‚ and streamlining workflows.

How AI is Revolutionizing the Process of Writing Books and Manuals

AI is transforming the writing process by automating tasks‚ enhancing creativity‚ and improving efficiency. Advanced tools now assist in generating content‚ suggesting narratives‚ and refining language. AI-driven platforms enable real-time research integration‚ reducing manual effort and ensuring accuracy. These technologies also facilitate personalized content creation‚ tailoring books and manuals to specific audiences. Additionally‚ AI aids in editing‚ proofreading‚ and formatting‚ ensuring polished outputs. The ability to analyze vast data sets enables AI to identify trends and optimize content for better engagement. While AI enhances human creativity‚ it also raises questions about authorship and originality. Overall‚ AI is reshaping writing processes‚ offering unprecedented opportunities for innovation and collaboration.

AI’s Role in Personalizing Content for Readers

AI plays a pivotal role in personalizing content for readers by analyzing data to tailor books and manuals to individual preferences. Through machine learning algorithms‚ AI identifies reader behaviors and interests‚ enabling customized recommendations. Content can be adapted dynamically‚ ensuring relevance and engagement. AI-driven tools also allow for real-time adjustments‚ refining the reader experience based on feedback. This personalization enhances learning outcomes and satisfaction‚ making complex information more accessible. By leveraging user data‚ AI creates a unique journey for each reader‚ fostering deeper connections with the material. This transformative approach ensures content is not only informative but also aligned with the reader’s specific needs and goals.

Challenges and Concerns in AI-Generated Content

AI-generated content for books and manuals raises significant challenges‚ including copyright and ownership issues. There are concerns about creativity and originality‚ as AI may mimic existing works. Additionally‚ the reliance on large datasets can lead to biases and inaccuracies. Ensuring factual accuracy and preventing misinformation is another challenge. Ethical questions arise regarding authorship and accountability for errors. Finally‚ the over-reliance on AI may diminish human creativity and oversight‚ potentially lowering the quality of content. These concerns highlight the need for careful regulation and human oversight in AI-generated books and manuals to maintain integrity and value in published works.

Book Discovery and AI-Driven Recommendations

AI is transforming how books and manuals are discovered‚ offering personalized recommendations and advanced search algorithms. These tools analyze content and user preferences to enhance accessibility and engagement for readers while opening new marketing opportunities for authors and publishers.

How Generative Search is Changing the Way We Discover Books

Generative search‚ powered by AI‚ is revolutionizing book discovery by analyzing entire texts and understanding user intent deeply. This technology enables personalized recommendations‚ uncovering hidden gems tailored to individual preferences. By leveraging advanced algorithms‚ generative search creates immersive experiences‚ such as interactive summaries and dynamic previews‚ making exploration more engaging. It also empowers authors to reach niche audiences more effectively‚ fostering diversity in reading choices. However‚ challenges like data privacy and algorithmic bias remain. Overall‚ generative search is transforming how we find and engage with books‚ offering unprecedented opportunities for readers and creators alike while reshaping the future of literature discovery.

The Role of AI in Recommending Books and Manuals

AI is transforming book recommendations by analyzing user behavior‚ preferences‚ and reading patterns to suggest tailored content. Advanced algorithms‚ including natural language processing‚ enable AI to understand complex queries and match readers with relevant books. This technology also identifies niche authors and titles that might otherwise go unnoticed. AI-driven recommendations adapt in real-time‚ evolving as user interests change. While these systems enhance discovery‚ challenges like data privacy and algorithmic bias persist. Despite these issues‚ AI’s ability to personalize and scale recommendations makes it a powerful tool for connecting readers with books and manuals‚ fostering a more dynamic and individualized literary experience.

Future Trends in Book Discovery and AI Integration

Future trends in book discovery will heavily involve AI-driven personalization‚ with systems learning user preferences to offer hyper-tailored recommendations. Generative search engines will analyze entire book texts to surface hidden gems. AI will also enhance discoverability through dynamic content previews and interactive summaries. Voice search and audio recommendations are expected to rise‚ making book discovery more accessible. Collaborative filtering will improve‚ linking readers with similar interests globally. These advancements aim to bridge the gap between readers and content‚ ensuring books reach their target audiences more effectively than ever before. As AI evolves‚ it promises to redefine how we uncover and engage with books and manuals.

Copyright and Legal Aspects of Books and Manuals

Understanding copyright laws is crucial for protecting intellectual property in books and manuals. Navigating audio rights and ensuring GDPR compliance are key legal obligations for publishers and authors today.

Understanding Copyright Laws for Books and Manuals

Copyright laws protect intellectual property in books and manuals‚ ensuring authors retain exclusive rights over their work. These laws prevent unauthorized reproduction or distribution‚ safeguarding creative and informative content. For copyrighted material‚ such as books‚ licensing audio rights is often necessary for narration. Authors and publishers must navigate these legal frameworks to avoid infringement. Understanding copyright laws is essential for creators and users alike‚ ensuring proper attribution and legal use of content. This protection extends to digital formats‚ maintaining the integrity of original works in an increasingly digital world.

Navigating Audio Rights for Copyrighted Material

Navigating audio rights for copyrighted material involves obtaining proper permissions to use or adapt the content legally. For books and manuals‚ this typically requires licensing agreements with the rights holder‚ ensuring lawful use of intellectual property. If the rights holder is unwilling to grant audio rights‚ alternative options like AI-generated narration may be considered‚ though this raises copyright concerns. Understanding the legal framework and ethical considerations is crucial to avoid infringement and maintain the integrity of the original work. Additionally‚ GDPR compliance must be addressed when handling user data in audiobook creation or distribution‚ ensuring personal information is protected.

Legal Obligations and GDPR Compliance in Publishing

Legal obligations and GDPR compliance are critical in the publishing industry‚ ensuring protection of personal data and adherence to privacy laws. Publishers must handle user information responsibly‚ as GDPR mandates strict guidelines for data processing and storage. This includes obtaining consent‚ anonymizing data when possible‚ and implementing robust security measures to prevent breaches. Failure to comply can result in significant fines and reputational damage; Additionally‚ publishers must ensure all content is legally cleared‚ with proper rights and licenses secured‚ especially for copyrighted materials. This ensures ethical publishing practices and avoids legal disputes.

GDPR compliance also extends to AI tools used in publishing‚ requiring transparency in data usage and ensuring no misuse of personal information. Publishers must stay informed about evolving regulations to maintain trust and legal integrity in their operations.

Marketing and Promotion of Books and Manuals

Effective marketing and promotion of books and manuals involve leveraging AI tools for targeted audience engagement and personalized campaigns‚ enhancing visibility and reach through innovative strategies.

Using AI Tools for Effective Book Marketing

AI tools are revolutionizing book marketing by enabling personalized campaigns and targeted audience engagement. Platforms like ChatGPT and Perplexity can analyze reader preferences‚ generate compelling content‚ and optimize promotional strategies. AI-driven analytics help identify trends‚ predict demand‚ and refine marketing messages for maximum impact. Additionally‚ AI can automate routine tasks such as email campaigns and social media management‚ freeing authors to focus on creative work. With AI‚ marketers can craft dynamic‚ data-driven approaches to reach readers effectively‚ ensuring books and manuals stand out in a competitive market. This integration of technology enhances efficiency and creativity‚ making AI indispensable in modern book promotion.

Brand Presence in AI-Generated Content and Search Results

Ensuring brand presence in AI-generated content and search results is crucial for authors and publishers. AI tools like ChatGPT and Perplexity can influence how brands appear in search outputs‚ raising concerns about visibility and accuracy. Marketers are exploring ways to optimize their content so that AI systems return their brands in search results‚ maintaining brand integrity and relevance. This involves understanding how AI algorithms rank and present information‚ ensuring consistent messaging‚ and leveraging data to enhance visibility. By aligning content with AI-driven trends‚ brands can improve their presence in the digital landscape‚ making their books and manuals more discoverable to target audiences.

The Role of Email Newsletters in Promoting Books and Manuals

Email newsletters are a powerful tool for promoting books and manuals‚ fostering direct communication with readers. They enable authors and publishers to share updates‚ insights‚ and exclusive content‚ building a loyal audience. By consistently delivering valuable information‚ newsletters help maintain reader engagement and trust. They also provide a platform to announce new releases‚ offer discounts‚ and gather feedback. Despite the rise of AI and digital tools‚ email newsletters remain a cost-effective and personalized way to connect with readers‚ making them a cornerstone of modern marketing strategies for books and manuals. Their measurability and targeting capabilities further enhance their effectiveness in driving sales and community growth.

Energy and Environmental Considerations

Books and manuals’ production raises environmental concerns‚ with AI-driven processes consuming significant energy. Comparing digital and traditional methods highlights the need for sustainable practices in publishing.

The Environmental Impact of AI and Digital Publishing

The shift to AI and digital publishing has sparked debates about its environmental impact. While AI processes consume significant energy‚ digital books reduce paper usage and physical distribution emissions. Sustainable practices‚ such as optimizing energy-efficient algorithms and using renewable energy sources‚ can mitigate AI’s carbon footprint. Additionally‚ digital manuals and books minimize waste from unsold physical copies. However‚ the production and disposal of electronic devices used for digital content remain concerns. Balancing technological advancements with eco-friendly strategies is crucial for a sustainable future in publishing.

Comparing Energy Usage of AI with Traditional Practices

AI and traditional practices differ significantly in energy consumption. AI models‚ especially during training‚ require substantial computational power‚ often relying on energy-intensive data centers. In contrast‚ traditional book and manual production involves printing‚ shipping‚ and storage‚ which also have environmental costs. However‚ AI-driven digital publishing reduces the need for physical materials and transportation‚ lowering carbon emissions. While AI’s energy usage is high‚ its ability to scale and optimize processes can lead to long-term efficiency gains. This comparison highlights the trade-offs between technological advancement and resource utilization‚ emphasizing the need for balanced approaches in modern publishing.

Sustainable Practices in Digital Book and Manual Creation

Digital book and manual creation offers numerous opportunities for sustainable practices. By minimizing physical materials‚ digital publishing reduces deforestation and lowers carbon emissions from printing and transportation. Energy-efficient data centers and cloud storage solutions further mitigate environmental impact. Additionally‚ tools like AI-driven content optimization can reduce redundancy and waste. Recycling and repurposing digital content also contribute to sustainability. Publishers are increasingly adopting eco-friendly server technologies and renewable energy sources to power their operations. These practices not only benefit the environment but also align with global efforts to reduce carbon footprints‚ making digital publishing a more responsible choice for future generations.

Books and manuals continue to evolve‚ blending tradition with AI-driven innovation. As technology advances‚ their role in education and professional growth remains vital‚ shaping future knowledge-sharing landscapes.

Summarizing the Key Takeaways

Books and manuals remain cornerstone resources‚ blending traditional value with modern advancements. AI has transformed writing processes‚ enabling personalized content and efficient discovery‚ while raising concerns about copyright and ethics. The shift to digital formats has sparked debates on environmental impact and energy consumption‚ urging sustainable practices. Marketing strategies now leverage AI tools‚ enhancing brand presence and reader engagement. Despite challenges‚ the integration of technology promises to enhance accessibility and innovation in knowledge sharing. Adapting to these changes is crucial for authors‚ educators‚ and professionals to thrive in an evolving landscape.

Preparing for the Future of Books and Manuals

As books and manuals evolve‚ embracing AI-driven tools and sustainable practices will be essential. Authors and publishers must adapt to personalized content demands while addressing copyright and ethical concerns. Investing in energy-efficient technologies can reduce the environmental footprint of digital publishing. Marketers should leverage AI for targeted promotions and maintain strong brand presence. Staying informed about GDPR compliance and data protection is crucial for legal obligations. By balancing innovation with tradition‚ the future of books and manuals will remain vibrant‚ accessible‚ and relevant in a rapidly changing world. Collaboration between creators and AI will shape the next chapter in knowledge sharing and education.